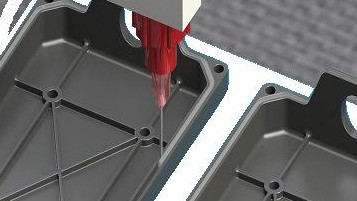

Dispensing

在塑料和橡膠工業工業中,等離子清洗技術針對聚丙烯,PTFE等橡膠塑料材料在印刷、粘合、涂布等過程,利用等離子技術進行表面處理,在高速、高能量等離子體的轟擊下,表面會產生一層活性層,這樣橡膠、塑料就可進行打印、粘貼、涂膠等操作,通過粘接連接涂料連接時,需要用等離子處理,使其完全潔凈、無氧化的表面,然后連接起來。

Oil injection, electroplating

Plasma pretreatment can remove the oil and dust on the surface of the material and make the surface energy of the material higher. The cleaning effect of plasma cleaning treatment technology can remove the surface oil, and the electrostatic action of plasma can remove the surface attachment. The dust particles on the surface, and the chemical reaction improves the surface energy. The integration of these aspects makes the plasma pretreatment process become an efficient means, which usually does not need to carry out plasma pretreatment, additional cleaning procedures and bottom coating treatment. Plasma pretreatment can ensure strong adhesion of metal materials such as aluminum, plastic materials such as PP or EPDM or other materials. Plasma processing technology is used to achieve reliable and durable bonding.

Color boxes and paper boxes

Plasma cleaners increase viscosity without damaging the surface of the package. The workplace is easy to clean and does not affect work efficiency. Plasma cleaners can help businesses save expensive glue costs. It can not only clean and remove stains, but also change the surface properties of the material itself. For example, improve the wettability of the surface and the adhesion of the film. Plasma surface treatment devices can target material surfaces to provide significant surface tension, resulting in good printing, bonding or coating quality in subsequent processing.

- 在線咨詢

- 微信咨詢

微信掃碼咨詢

- Tel

- Phone0755-81452366

- Tel13510501616

- Top